In the realm of modern infrastructure development, the importance of high-density polyethylene (HDPE) pipe fittings cannot be overstated. As pivotal components in plumbing, irrigation, and industrial systems, these fittings play a crucial role in ensuring seamless fluid conveyance, safeguarding structural integrity, and promoting operational efficiency. In this comprehensive guide, we delve into the intricacies of HDPE pipe fittings, elucidating their functions, materials and myriad applications.

What Are Pipe Fittings?

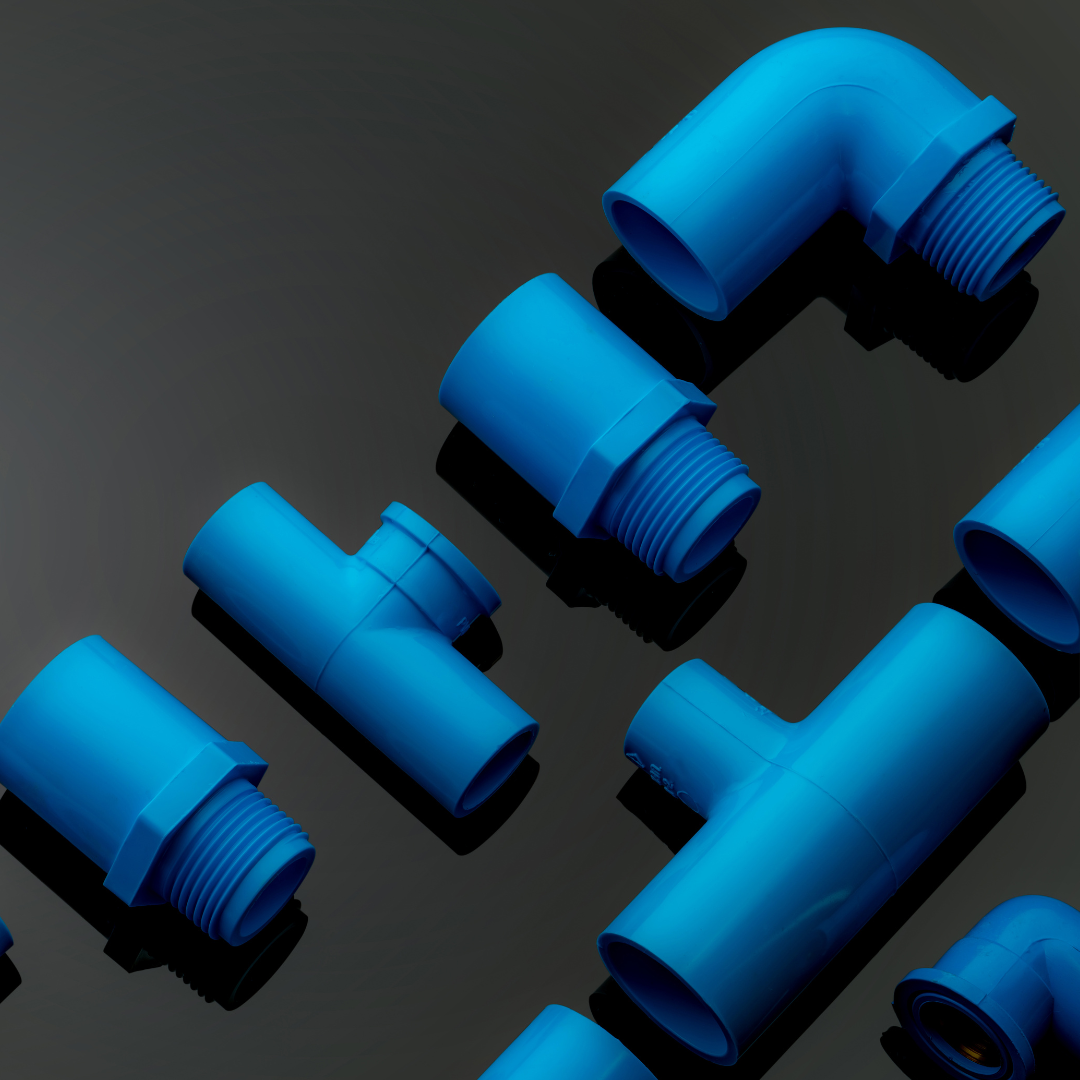

Pipe fittings serve as indispensable connectors, facilitating the joining of pipes or tubing sections and enabling directional flow, diversion, or regulation of fluids. These fittings come in an array of shapes, sizes, and configurations to accommodate diverse piping requirements, ranging from simple couplings to complex elbows, tees, reducers, and valves. By providing secure and leak-proof connections, pipe fittings mitigate the risks of system failure, leakage, and contamination, thus ensuring the reliability and longevity of fluid transmission networks.

The Utility of HDPE Pipe Fittings:

HDPE pipe fittings offer a myriad of advantages, making them a preferred choice across various industries:

1. Corrosion Resistance: HDPE fittings exhibit exceptional resistance to corrosion, abrasion, and chemical deterioration, rendering them suitable for conveying corrosive fluids, wastewater, and chemicals without compromising structural integrity.

2. Flexibility and Durability: With superior flexibility and toughness, HDPE fittings can withstand dynamic loads, ground movement, and temperature fluctuations, ensuring longevity and resilience in demanding environments.

3. Lightweight Construction: Compared to traditional metal fittings, HDPE fittings are significantly lighter, simplifying handling, transportation, and installation while reducing labor costs and logistical complexities.

4. Leak-Free Joints: Utilizing advanced fusion welding techniques such as butt fusion, electrofusion, or socket fusion, HDPE fittings ensure leak-free joints with seamless integration, minimizing maintenance requirements and operational disruptions.

5. Environmental Sustainability: As environmentally friendly alternatives to conventional materials, HDPE fittings are recyclable, non-toxic, and inert, minimizing environmental footprint and promoting sustainable development practices.

Materials and Manufacturing:

HDPE pipe fittings are typically manufactured from high-density polyethylene resin, a thermoplastic polymer renowned for its exceptional mechanical properties, chemical resistance, and thermal stability. The manufacturing process involves extrusion, injection molding, or compression molding techniques to produce fittings of precise dimensions, geometries, and performance characteristics. Advanced manufacturing technologies enable the production of HDPE fittings with stringent quality control measures, ensuring compliance with industry standards and specifications.

Applications and Industries:

HDPE pipe fittings find widespread applications across diverse industries and sectors:

1. Water Supply and Distribution: HDPE fittings are extensively used in municipal water supply networks, irrigation systems, and potable water distribution networks due to their corrosion resistance, longevity, and hygienic properties.

2. Chemical Processing: In chemical plants, refineries, and industrial facilities, HDPE fittings facilitate the conveyance of acids, alkalis, solvents, and corrosive chemicals, offering superior chemical resistance and reliability.

3. Mining and Slurry Transport: HDPE fittings play a vital role in mining operations for transporting abrasive slurries, tailings, and mine water, offering abrasion resistance, flexibility, and ease of installation in rugged terrains.

4. Infrastructure Development: From sewerage systems and stormwater management to culvert pipes and trenchless applications, HDPE fittings contribute to sustainable infrastructure development with their durability, versatility, and cost-effectiveness.

Conclusion:

In conclusion, HDPE pipe fittings epitomize the fusion of innovation, efficiency, and sustainability in modern fluid conveyance systems. With their exceptional performance attributes, versatile connection methods, and diverse applications, HDPE fittings continue to redefine the standards of reliability, durability, and efficiency in the piping industry. As the demand for robust, corrosion-resistant, and environmentally conscious solutions grows, HDPE pipe fittings emerge as indispensable components, empowering industries to overcome challenges and embrace the future of fluid transmission with confidence and resilience.