1. Thermal stability test (oxidation test): The time when the antioxidant additive in polyethylene prevents oxidation at high temperature.

2. Black carbon quantity analysis (ISO 6964): Is done by determining the amount of carbon (%) added to make the HDPE pipes UV resistant.

3. Density test (ISO 1183): Made in order to calculate the weight of the HDPE pipe per volume unit. The sample is initially weighed in air and then in a liquid whose density is known in advance. The density is also found using the calculation described in the standard.

4. MFR (melt flow rate) test (ISO 1133): An application made to test the behavior of the material that will be used in relation to temperature before processing it. The values found in the test with the MFI device were loaded into the device and calculated in grams per ten minutes. The result is determined using the unit.

5. Tensile strength (ISO 527): The test includes determination of the tensile strength and the elongation at the breaking point. The tensile properties test is performed to determine the properties used in production, and is valid for any thermoplastic pipe.

Hydrostatic pressure test (ISO 9080 EN 921): This is the test that is done to PE100 pipes under accelerated environmental conditions to examine their behavior under pressure over time. In this test you can see the changes that PE100 pipes will go through over 50 years.

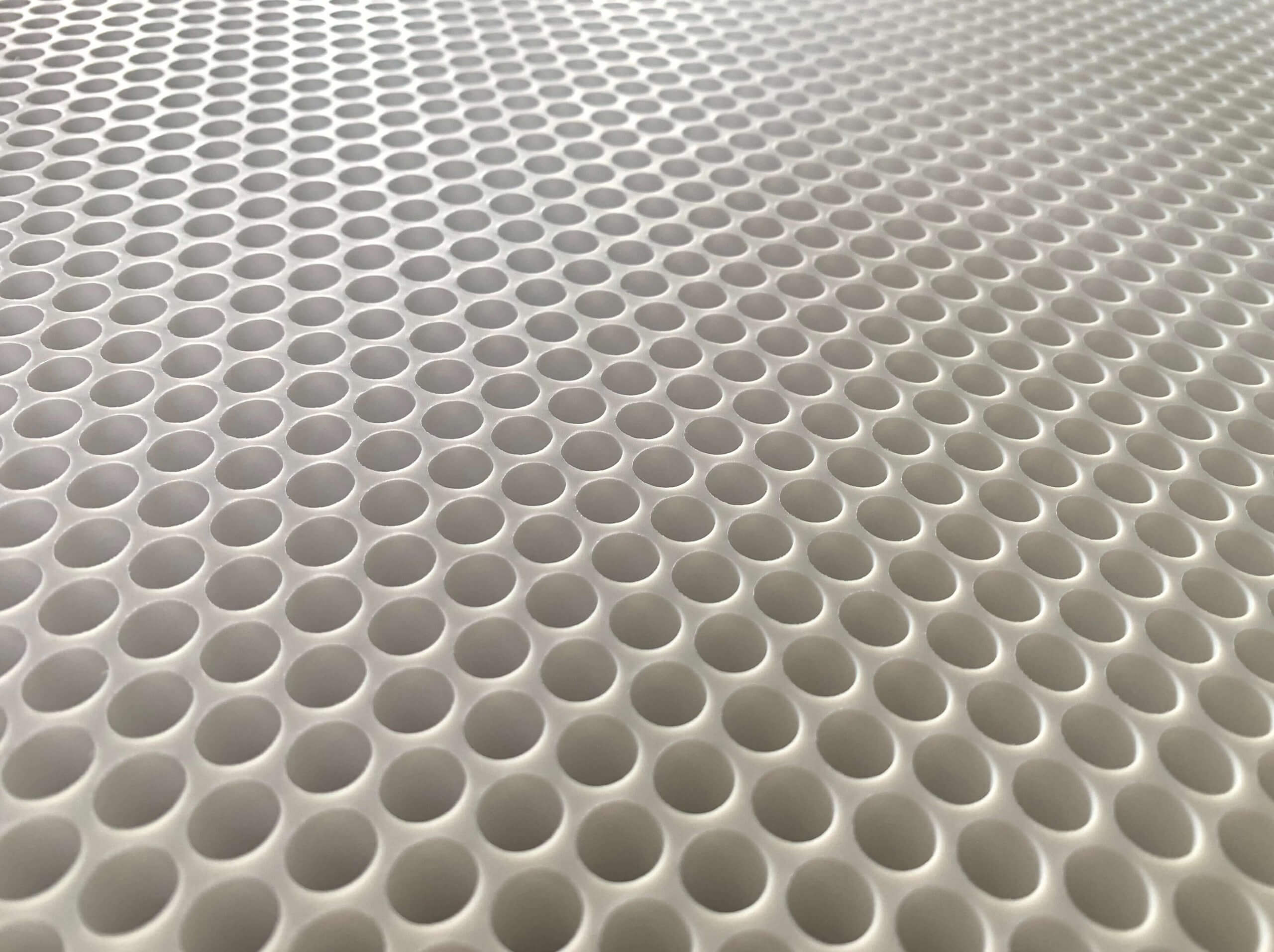

Homogeneity test (ISO 13949): It is done in order to examine the uniform distribution of the pigment and possible structure gaps in the material. The microtome sample taken at a thickness of 10-15 microns is examined under a microscope.